https://ichemeblog.org/2020/07/28/climate-change-hazards-and-digitalisation/#more-12210

Digitalisation is one of the three priority topics for IChemE (Institution of Chemical Engineers UK) learned society. IChemE needs to understand how the development of digital technologies will change the profession, and use members’ expertise and that of fellow professional engineering institutions to support IChemE members in all stages of their careers with relevant information, resources and opportunities for discussion.

IChemE is currently setting up a Technical Advisory Group (TAG) to develop this work. Recognising Auckland’s leadership in this discussion, e.g. via the recent alumni survey (see report of survey results below), Chemmat’s Professor Brent Young has been appointed to be Deputy Chair of the TAG. IChemE were also delighted to have had a strong response from IChemE members volunteering to join this group, which will first meet this month. If you have any digitalisation perspectives you wish to share with Brent, please contact him (b.young@auckland.ac.nz, 09 923 5606).

Interim report:

University of Auckland Digitalisation project survey results

by Chemmat’s Dr Isuru Udugama, Dr Wei Yu and Prof Brent Young

Summary

This report contains the interim survey results that have been gathered for the purpose of introducing industry 4.0 (i4.0) elements in the to the Chemical and Materials Engineering (CHEMMAT) undergraduate syllabus at the University of Auckland. The Survey results consists of three surveys that targeted:

- International Academic and industry Experts in i4.0, where the questions were intended to identify which 0 elements area of use to chemical engineers and to what extent they should be covered in an undergraduate syllabus.

- CHEMMAT Alumni, where the questions were intended to identify the current levels of digitalization at workplaces and what is expected in the

- CHEMMAT Staff, where the questions were intended to identify the staffs opinion on different i4.0 elements and more importantly where these elements can be placed in the CHEMMAT Syllabus

All three surveys asked the responder’s opinion on whether these digitalisation and i4.0 concepts should be covered as a standalone course and/or embedded in the syllabus. The objective of this separate and distinct surveyors was to identify clearly 1) the opinion of “global leaders in the topic”, 2) the perceived value for the “beneficiaries” of such a course upgrade change, and 3) the individuals that must facilitate such a change.

Overall the results obtained from the survey show a positive response from all three groups surveyed to introducing I 4.0 elements into the course with all three surveys endorsing a combined embedded teaching and a stand-alone module approach. The international experts point out concepts such as IOT and Machine learning and full on Digital Twins might need to be taught at a lower level of complexity (as per Bloom’s Taxonomy) due to time limitations. The Alumni overwhelmingly think digitalisation will be of important in the next 10 years, however there are handful of strong opponents of i4.0 concepts, mainly due to the past promises given by proponents of concepts such as big data analytics which did not materialise. To this end, it would be beneficial for all these new i4.0 concepts to be taught with a strong emphasis on their limitations as well. Finally the staff agree on the use of making students familiar with mathematical tools and digital models, but are divided in opinion of the usefulness of full digital twins as well as machine learning, IOT concepts.

Based on the analysis the authors of the survey have the following preliminary conclusions (subject to revision):

- Regression and mathematical tools should be used more in 2nd year chemical engineering courses such as thermodynamics

- Digital model building should be an embedded assignment in a 3rd year CHEMMAT Subject

- Digital twins, machine learning and IOT should be taught at a lower level to students in general, while a dedicated course should be created to teach these concepts in 4th

- More 4th year projects should be dedicated to instrumenting, automating and making digital models of existing unit operations which can then be used to demonstrate digital shadow and digital twin concepts to 3rd years in hands-on lab sessions. (This reduces the development costs and allows training of students at the same time).

Key Highlights

Academic and industry Experts: At the time of this report 16 responses have been recorded in the survey with 7 respondents identifying as “senior” academics and 9 identifying as industrial experts. The figure below shows the areas of research/expertise they fall into.

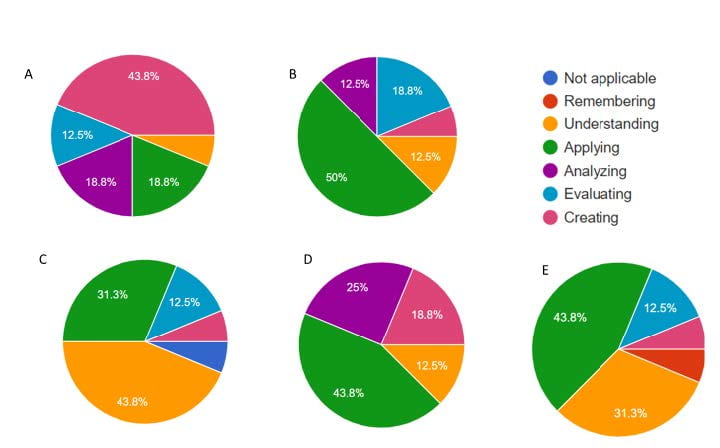

The experts were asked 5 questions with regards to identifying which i4.0 elements are of importance to the chemical engineers and at which level they should be introduced in the CHEMMAT undergrad syllabus. The figure illustrates the answers to these questions.

A. The use of digital models to represent key unit operations

B. The use of digital twins in conjunction with unit operations (for example in lab and pilot scale facilities)

C. The use of IOT technologies such as smart sensors and digital infrastructure

D. The use of statistical methodologies (regression and classification methodologies)

E. The use of machine learning techniques (prediction and classification)

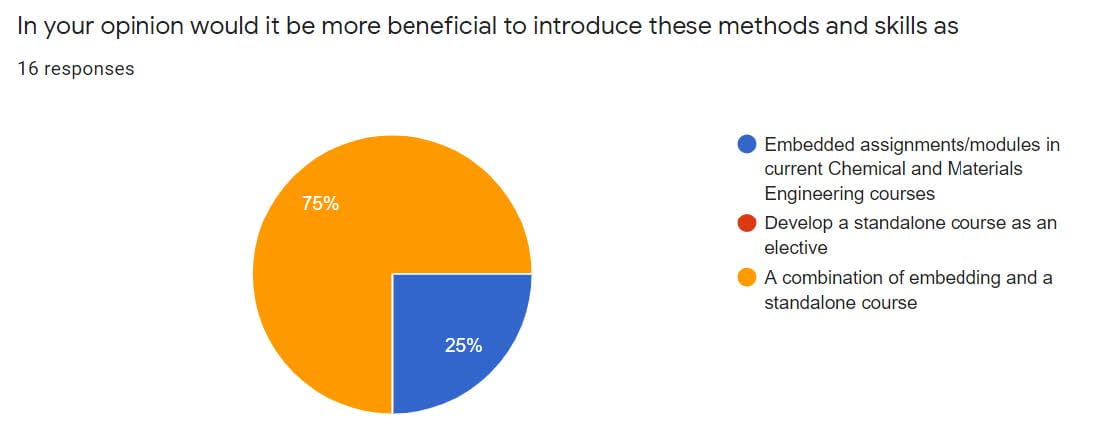

Overall Analysis: The experts on average place a high level of emphasis on all aspects of digitalisation elements with the least importance put on IOT. Some experts question if the Undergrad syllabus in CHEMMAT has space to introduce machine learning and statistical analysis methods. To this end the We believe the emphasis should be on Digital Models and Digital Twins with less focus on statistical methods and machine learning, and IOT is only touched upon. Finally the Experts overwhelmingly believe a combined approach of embedding and standalone course development should be carried out.

The Alumni

At the time of this report 47 responses have been recorded in the survey with respondents identifying their current role as Engineer/manager Process design, Engineer/manager Operations, Engineer/manager product development, Academic/ R&D in Engineering, Quality management, Financial/Business Sector Manager, Government Official, Technical Safety and Risk Engineer, Impact Venture Capital, Business Development & Sales, Process Safety, Project manager, CEO, Strategy Manager, Project Management, Pharmaceutical/drug development in over 10 distinct industries.

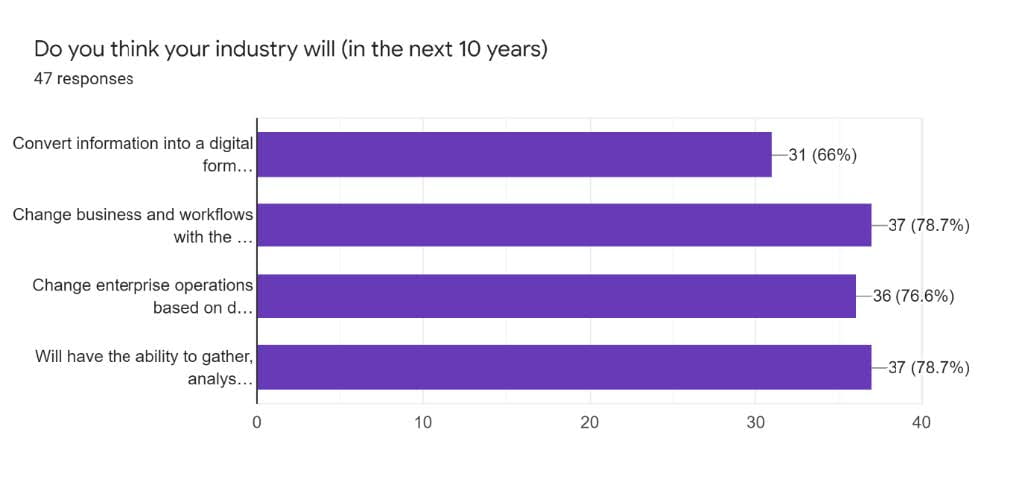

When asked about where their industry will be heading in the next 10 years the responders thought many of the transformations that would be enabled by industry 4.0 concepts would be of importance and that the industry would embrace it. Namely these changes are:

A. Convert information into a digital format (i.e. computer readable)

B. Change business and workflows with the use of digital information

C. Change enterprise operations based on data

D. Will have the ability to gather, analyse data and make decisions in real time

However, only a handful of individuals currently have an industry where:

a) Taking decisions is based on forecasting models

b) They have the ability to gather, analyse data and make decisions in real time based on the analysis

When asked, the opinions of the alumni on where to place such materials, most believed a combined embedded approach would be sound as illustrated in the figure below

The overall conclusion is that all digitalisation elements are of importance to the diverse industries which CHEMMAT undergrads seems to go into.

The Staff

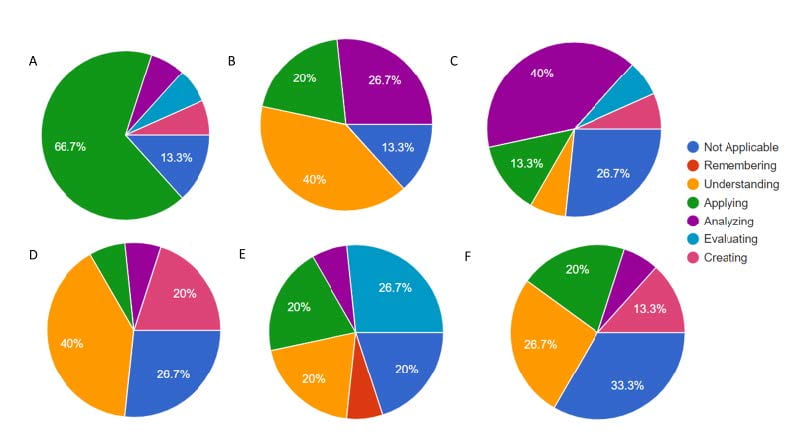

At the time of this report 16 responses have been recorded in the survey with 1/3 of responders identifying themselves as either Professors (including Associate Professors), Lecturers or Teaching/Research Fellows, As such the survey reflects the viewpoints of both experienced and early career individuals. About 40% of the individuals also perform research in the area of Materials. The figure below shows the responses obtained for 6 key questions related to covering different core concepts that need be a part of an i4.0 based Chemmat Syllubus, with an emphasis on where exactly to place these elements in the CHEMMAT undergrad curriculum.

A. The use of computer based tools (such as Excel, Matlab, Python and R) to solve mathematical formulations?

B. The use of digital models to represent unit operations?

C. The use of multi-variate statistical data analysis methods?

D. The use of digital twins to represent and communicate with physical unit operations, for example a lab set up?

E. The use of machine learning methods for parameter estimations?

F. The use of digital infrastructure to facilitate digitalisation of processes?

When asked about the preferred method to incorporate these concepts into CHEMMAT, the following responses were obtained. 6 individuals said some part of their course can be given to teach these concepts, 5 believed a stand-alone course is the way to go while 5 believed a combined approach is ideal.

Overall a positive response from the CHEMMAT staff is also observed with useful suggestions around where to place some of the key concepts in the syllabus. However, there are some staff who may doubt the usefulness of some of the concepts discussed. Careful consideration must be given to addressing these doubts.