Food comes in all shapes, sizes and textures. And now you can print your own food.

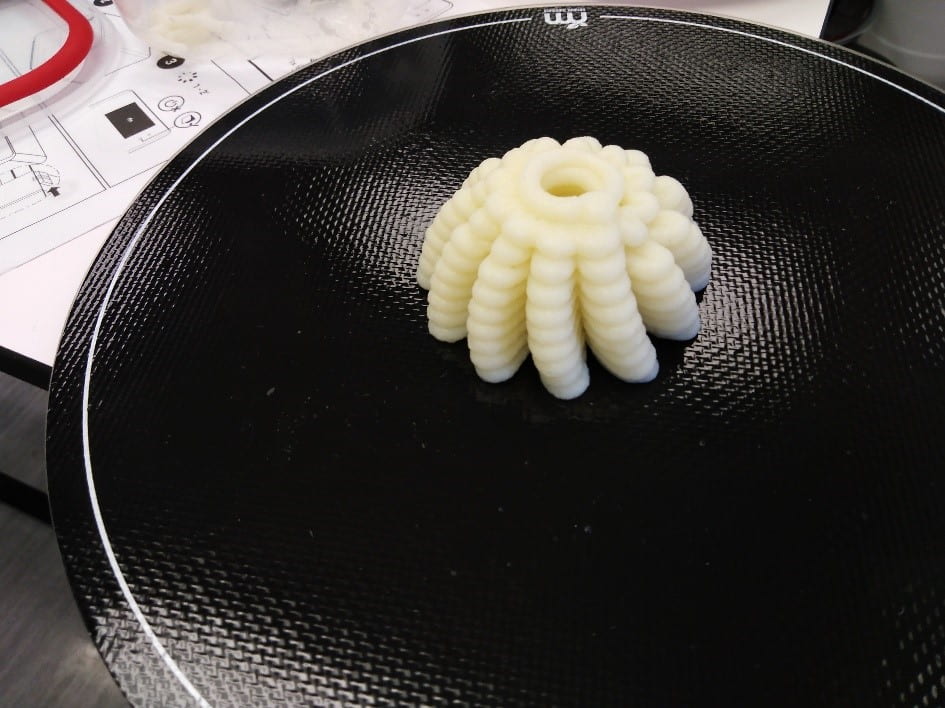

Chemmat has recently obtained a Foodini 3D Food Printer. The Foodini works on the principle of food paste extrusion and has the capability to print five different food materials within a single print. This allows composite food structures to be designed and printed to accommodate specific sensory or nutritional requirements. The printer is currently equipped with 0.8, 1.5 and 4.0 mm printing tips to cater for food pastes of varying viscosities and to print with varying resolutions. This is coupled with heating capabilities in the printing head. Some of the common food materials which can be printed are mashed potato, chocolates, cream cheeses, cheese etc. There are also more than 20 pre-set food designs in the Foodini, but users can upload their own. The printer can also create gelatin based structures.

In the exploration of new food paste formulation and design, users often face the challenge of selecting suitable food paste consistency-printing setting combinations. Wai, Sophia and Josh from Chemmat, with the support of the FRDF New Staff Fund, are currently looking at predictive approaches to minimize the guesswork involved in such gastronomical exploration.

As part of this project, two Part 4 students (Patricia Ordona & Vivien Hsiao) and a postgraduate student in Food Process Engineering (Yulun Zheng) are now focusing on the printability of meat paste.

“Getting the meat paste right is important … we had to manually pick out the tough fibers,”

echoed Patricia and Vivian,

“Then comes the art of setting the printer.”

The Foodini is now located in the Food Lab in Bld529 and is available for use. Please contact Wai for the required training. Let’s hope the team makes some headway into the predictive approach for chocolate printing before Valentine’s Day next year!